Putting the framing on a house can be a time consuming and repetitive task

You never stop looking for more efficient, time-saving solutions to complete your projects. One of the most time-consuming parts of the build will be putting together the framing on a house, the traditional approach to getting this done involves the repetitive that involves moving and clmbing ladder.

The Solution

Our friends at Simpson Strong Ties have come up with product solutions that don't require:

|

SDWS - Top and bottom plate to stud

|

SDWS - The Strong‑Drive® SDWS is the 2nd generation structural screw, redesigned with a patented SawTooth™ Point. It delivers faster starts, less torque, and eliminates the need for pre-drilling, which means more screws installed and less labour for you compared to conventional installation. All this reduces tool wear and extends your battery life! Bold Threads design provides superior holding power, even into the end grain of timber. The Head stamped for easy identification of length and diameter, for building certification. The SDWS is the advanced alternative to bolting timber, or batten and coach screws, being 30% faster and 10% stronger than an equivalent batten screw. Designed to be versatile the SDWS is recognised as a solution for timber connections and is backed by testing and load data.

Applications:

- Outdoor Structures

- Deck Frames and Ledgers

- Landscaping

- Structural Timber Framing

|

SDWC - Rafter and truss to top plate

|

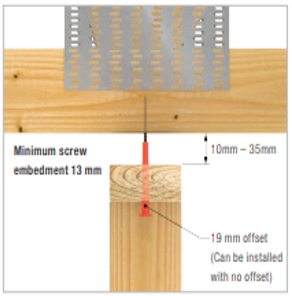

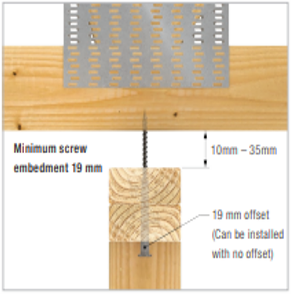

The Strong‑Drive® SDWC Truss Screw provides a truss and rafter-to-top plate connection as well as a method to fasten stud-to-top and bottom plate. The fully-threaded shank engages the entire length of the fastener providing a secure connection. The SDWC uplift values listed were analysed and calculated based on the characteristic values determined following AS1649-2001 (Timber-Methods of Test for Mechanical Fasteners and Connectors-Basic Working Loads and Characteristic Strength). The SDWC has also been tested in accordance with ICC-ES AC233 (screw) and AC13 (wall assembly and roof-to-wall assembly) for uplift and lateral loads between wall plates and vertical wall framing and between the top plate and the roof rafters or trusses.

It replaces strapping, which means, no interference with wall cladding, Lintel Screw, Coach Screw, Lag Screw, Landscape Screw, Structural Screw, Ledger Screw, Retaining Wall Screw, Boundary Joist Screw, Deck Post Screw

Cap Head countersinks fully into the double top plate to avoid interference with plasterboard or finish trades and is orange in colour for easy inspection of 152 mm screws in the structure. The fastening can be performed before or after exterior sheeting is applied for added flexibility while eliminating exterior work on the upper stories results in and enhanced job safety

Wide tolerance on installation angle makes it easy to install the SDWC correctly — Installation guide included to help ensure proper installation angle.

Applications:

- Truss/Rafter-to-Top Plate connection

- Stud-to-Top and Bottom Plate connection

|

Quik Stik - Rafter and truss fastening system

|

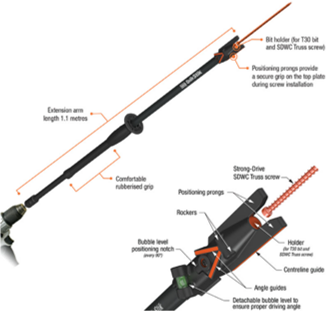

Introducing the new standard for overhead assembly installations of rafter and truss connections. The Simpson Strong-Tie® Quik Stik™ installation tool provides contractors with a versatile solution that makes fastening rafter and truss connections fast, safe and easy.

Quik Stik™ and Strong-Drive® SDWC Truss screws are designed to work together for a safe, reliable solution! Makes installation Faster, Driving e screws overhead from a standing position with no ladders. Safe on the jobsite: Designed for use inside the structure — no need to work outside the building. It is the specifically for use with the Strong-Drive® SDWC Truss screw for rafter/truss connections referenced above.

Designed specifically for use with the Strong-Drive® SDWC Truss screw for rafter/truss connections with Nylon over-moulded head it positions prongs that provide a secure grip on top plate, Angle and Centreline guidelines to correctly position the SDWC Truss screw for installation and adjustable bubble level to ensure proper installation screw angle. Its Comfortable rubberized grip and Long extension arm (1.1m) for reaching overhead top plate/rafter connections make it comfortable and easy to use.

Simpson Strong-Tie’s SDPW Deflector Screw is a premium structural fastening solution that provides a time-saving solution for non-load-bearing walls to trusses and joists. The screw makes a connection that slips on demand with vertical displacements of the floor or the supporting ceiling joists or truss chord while providing resistance to horizonal forces. With tested lateral-load ratings the SDPW screw is value engineered for strength, installation speed and safety. The Deflector Screw also includes a head offset from the bottom of the plate. The SDPW Deflector Screw solution involves during a single screw per connection point up through the partition wall top plate and into the joist or bottom cord of the truss. A partition wall fastened with SDPW Deflector Screws and with drywall correctly detailed will facilitate differential movements without damage to the drywall. Deflection solutions involving metal-on-metal fastening are prone to squeaking when movement occurs. SDPW Deflector Screw Solution’s polymer sleeve acts as a friction barrier between the fastener and top plate, thus preventing squeaks.