The Magic Behind Bonding and Sealing

Moisture curing products are like the superheroes of bonding and sealing. They are commonly known as silicones, polyurethanes, and hybrid polymers in this league. What makes them unique is that they need a bit of moisture from the air to trigger their curing magic. But when they come across porous substrates, those substrates share their moisture too which affect the curing process.

If you're in a hurry and want these products to work their magic faster, just turn up the temperature and humidity levels, doing so will make the curing process go quicker.

The Impact of Substrate Types on Cure Time

Now, let's explore some specific bonding scenarios to see how moisture comes into play:

Bonding of Aluminium (Non-Porous) to Steel (Non-Porous):

In this case, the adhesive will only have access to atmospheric moisture to cure. This results in a slower full cure time since it relies solely on the moisture in the air.

Bonding of Timber (Porous) to Steel (Non-Porous):

Here, the adhesive has access to atmospheric moisture and will also draw moisture from within the timber. The porous timber acts like a moisture reservoir, giving the adhesive more moisture to work with, which can speed up the curing process compared to the aluminium-steel scenario.

Bonding of Timber (Porous) to Timber (Porous):

In this scenario, the adhesive has access to atmospheric moisture and can draw moisture from both porous substrates. This results in the fastest full cure time as it gets a moisture boost from both sides.

Optimising Cure Speed

Temperature and humidity

So, as you can see, the nature of the substrates involved in the bonding process can significantly impact the curing speed of these moisture curing products. Non-porous materials like aluminium and steel may have a slower cure time since they rely solely on atmospheric moisture. However, when porous materials like timber are involved, the curing process can speed up as the adhesive taps into the moisture from both the atmosphere and the porous substrate.

Bonding applications

When using a moisture cure product for bonding, the ideal way to apply the adhesive is in continuous beads, rather than in daubs.

When a moisture cure adhesive is applied in beads, the adhesive will reach full cure 5-10 times faster than daubs as the moisture from the air needs to go through the cured adhesive and reach the centre.

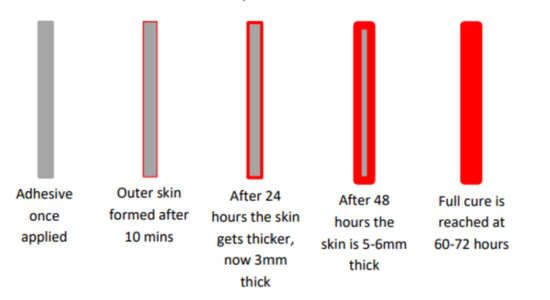

The diagram below illustrates that the adhesive gradually cures over time. However, as the moisture has to make its way through the outer layer, and this layer thickens, the curing rate per 24 hours slows down. If the two substrates were pulled apart before the adhesive fully cured, the adhesive in the middle would still be wet:

Curing time for beads*

*Bead width: 12mm; Skin time: 10mins; Curing rate: 3mm per 24 hours

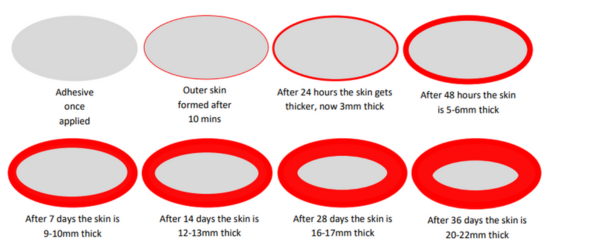

Curing time for daubs*

*Daub size: 90x50mm; Skin time: 10mins; Curing time: 3mm per 24 hours

Below are examples of two applications where moisture curing products were applied between two pieces of metal

As you can see the centre is still wet, you can tell this by the “ripple” effect.

Adhesive products at nhs

If you’re looking for the best adhesive to use on your project visit our website to shop the full range of adhesives available or get in touch with our team for a chat.