Our friends from Soudal have shared their top tips in joint preparation for sealants to help ensure that the right application avoids common issues that occur over time.

Definitions

Sealant: Material used to fill or seal the join

Side of the joint: area where the sealant connects to the joint

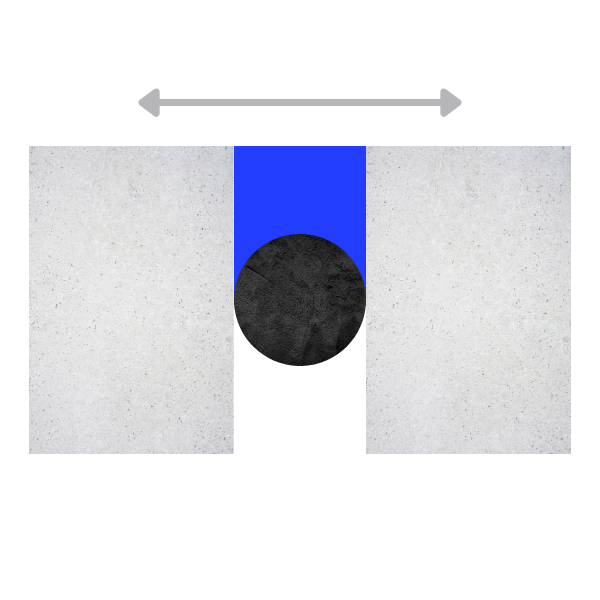

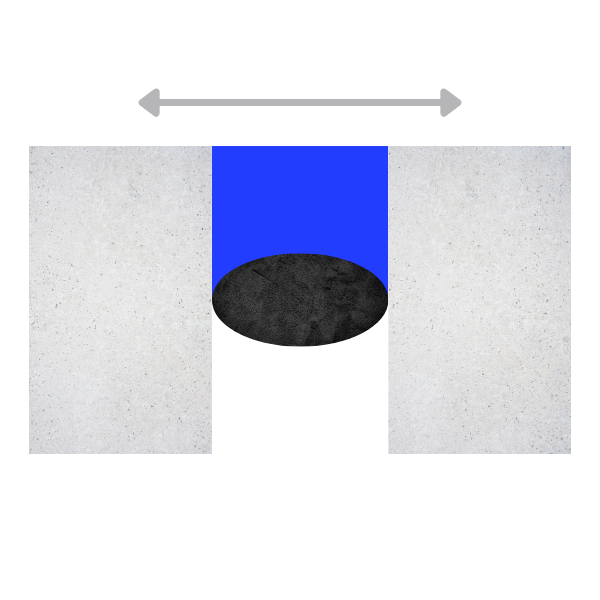

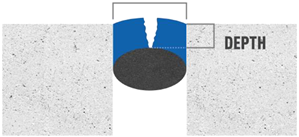

Depth of the joint: The depth of a joint which is required to be filled with a sealant to get a correctly performing joint.

Width of the joint: The width between the two sides of the joint

Backing material: PU or PE material which is used in a joint to define the depth of the joint and to prevent 3-point adhesion

Joint movement: Every change in the width of the joint due to:

-

- Temperature difference

- Difference in humidity

- Movement of the building elements due to shrink/expansion

- Movement due to environmental circumstances (traffic, earthquakes, etc.)

Types of joints

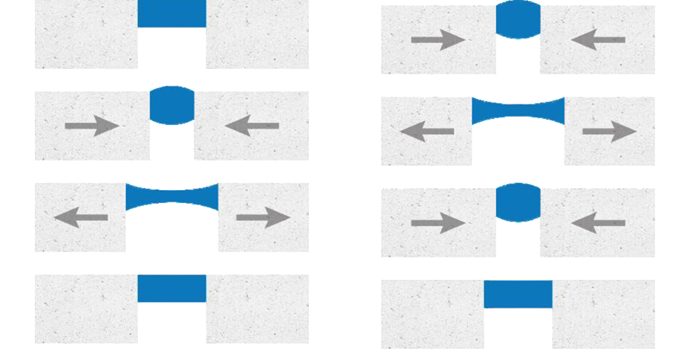

Static joint: Movement of the joint between the elements is less than 7% (+/- = expansion/contraction)

Connection Joint: Movement of the joint between the elements is between 7% and 15% (+/- = expansion/contraction)

Expansion joint: Movement of the joint between the elements is between 15% and 25% (+/- = expansion/contraction)

Joint Preparation for the application of sealants

To ensure the best results, check ensure that your joints are properly prepped before applying adhesives:

- The joint surfaces need to be:

- Dust-free

- Stable (free of loose material)

- Free of grease

- Dry

- Use backing material to achieve the correct joint dimensions and prevent 3-point adhesion

- Common preparation include:

- New joints:

- Surface preparation

- Primer

- Others

- Previously sealed joints

- Cut out existing sealant

- Surface preparation (grinding)

- Primer

- Others

- New joints:

Computing for sealant application based on joint dimensions

Using the correct dimensions will ensure high sealant performance over many years. The joint dimensions will determine the depth of the sealant. Another factor to consider in the computation is the type of sealant that you are going to use.

| Elastic Sealants (Silicone, Polyurethanes, Hybrid (SMX)) | Acrylics and Butyl Mastics | |

|

Joint size from 5-11mm

depth=width (e.g. 5mm wide=5mm deep) |

Joint size from 12mm to max width

depth=half the width (e.g. 12mm wide=6mm deep) |

All recommended joint sizes

depth=width (e.g. 5mm wide=5mm deep) |

Joint movement over time with the correct sealant depth:

Common issues

|

Width > Depth / 2 (Adhesive failure)

|

|

Width < Depth / 2 (Cohesive failure) When the joint stretches there is not enough sealant resulting in a weaker joint which can break more easily |

|

3 points adhesions will lock the sealant to 3 sides not allowing free movement, this will cause cracking in the adhesion. A possible solution is the use of a backing rod |

|

Cracking also occurs if the joint movement exceeds the maximum allowed distortion, this causes the sealant to stretch and eventually tear. Ensure that you select the correct product for the application. |

NHS Stocks a wide range of sealants for different applications

Our stores stock a range of Soudal sealants that have been engineered and manufactured for a wide range of applications.