With condensation related problems on the increase in Australia, the onus is on architects and builders to ensure they put preventative measures in place in new builds that will encourage ventilation, prevent dampness and manage condensation.

While moisture can impact on a new building’s aesthetics, especially in the form of unsightly Mould or mildew, it worryingly can also have lasting long-term effects on the health of a home’s inhabitants.

Putting appropriate condensation management measures in place during the design stage will result in the most cost-effective, efficient and healthy way to deal with moisture in residential building projects.

Recent changes to the National Construction Code (NCC) which came into effect from the 1st of July 2024, are designed to further enhance the Standard and further decrease health risks and building damage associated with high moisture levels in new homes. This Provisions build on NCC 2019 Provisions.

Condensation Management provisions have become an additional for builders to address – and a rethink of ventilation will be required, with help from our friends at ALPINE VENTILATION.

At NHS we constantly on the lookout for product which can make you already difficult job easier. Here is a guide to builders to assist in ensuring compliance for residential detached homes (Class 1) – and provides addition product improve the management of condensation in homes.

Section 10.8.1 relates to vapour permeable building membranes and has not changed.

Where a pliable building membrane is installed in an external wall, it must—

- comply with AS 4200.1; and

- be installed in accordance with AS 4200.2; and

- be located on the exterior side of the primary insulation layer of wall assemblies that form the external envelope of a building.

10.8.2 (Exhaust Systems)

What are the Key Implications?

- Exhaust fans, rangehoods and vented clothes dryers are required to be vented externally to outside air

- Exhaust fans must have a minimum flow rate requirement of up to 40L/s

- Some exhaust fans must be connected to the light switch with a 10-minute run-on time

Can I still vent exhaust fans or kitchen rangehoods into the roof space instead of venting externally?

No. This is no longer an option under the updated NCC 2022 provisions.

Should I vent out via the roof, eave, wall or fascia?

All locations have advantages and disadvantages. Most homes have multiple appliances requiring external ventilation and a combination will likely be required in most home.

10.8.2 Exhaust Fans

A compliant exhaust fan must have a minimum flow rate of 40L/s (144m3/h) in kitchen or laundry or 25L/s (90m3/h) in bathroom or sanitary compartments. The fan must also be ductable. In many situations, the fan requires a run-on timer. Ideally these are inbuilt (to save time and reduce cost) – but can also be wired in separately.

Alpine has a range of powerful header box exhaust fans that are ideal for venting out via 150mm ducting.

- 104L/s (375m3/h) flow rate (significantly above minimum flow rate requirement)

- DIY installation – plugs - Low clearance – 210mm - Low noise - Japanese ball bearing motor – tested to 50,000 hours - Round cut-out with fast swing clips for easy installation - 3-year warrantee

The RF250 is ideal for naturally ventilated rooms and the RFT250 (with timer) is ideal for non-naturally ventilated rooms.

The timer version has 2 simple plugs for DIY installation and requires no hard wiring.

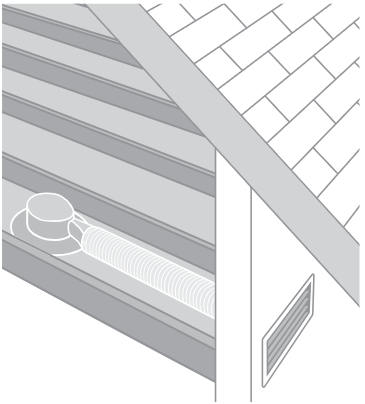

10.8.2 Ducting and Accessories

Fans need to be ducted externally to roof, wall, eave or fascia vents. Alpine Ventilation has a range of flexible and semi rigid ducting (AS1530 and AS4254 compliant) and accessories required for installation such as connectors, adapters, duct tape and clamps. They come in a variety of diameters, with 150mm being the most commonly used size.

Shop online for Ducting and Accessories

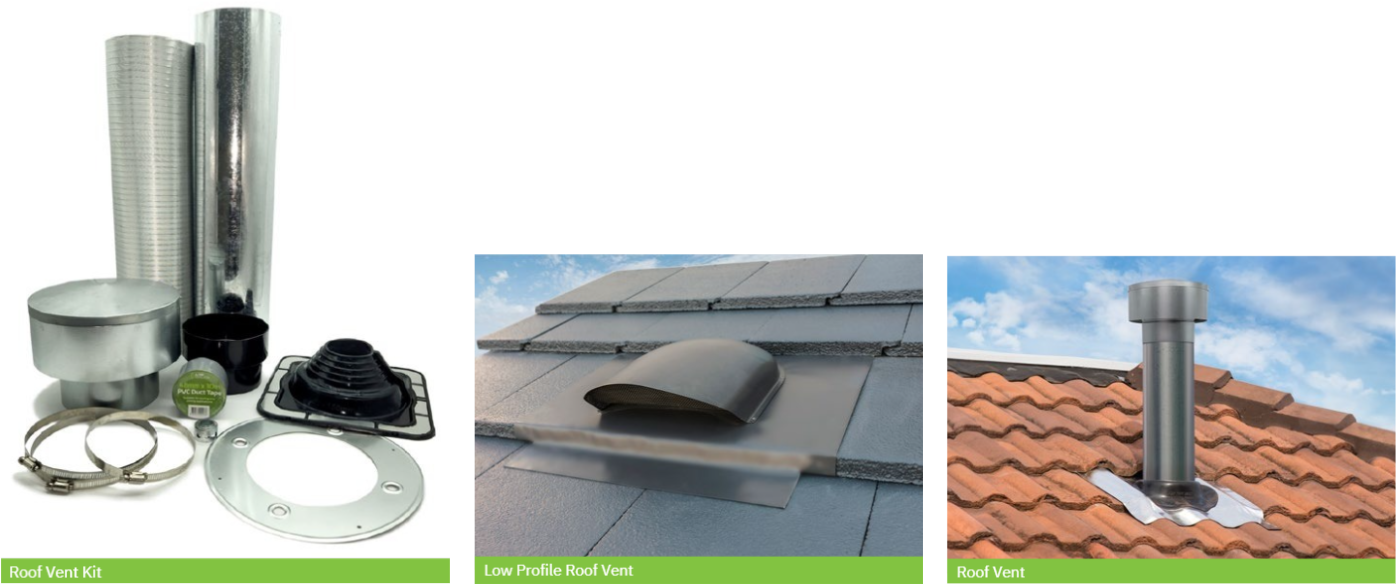

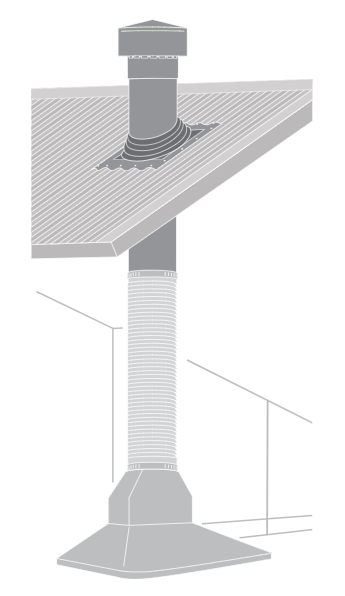

10.8.2 Roof Venting

|

Most homes will utilise roof venting for some air extraction as it is relatively simple and accessible as a method. For fans and rangehoods requiring roof venting, Alpine Ventilation provides 3 options – traditional kits for metal or tiled roofs, components (mushroom cowls, pipe and flashing) or the new low profile roof vents. We generally recommend the low-profile roof vents for the following reasons: - Visually appealing and discrete - Static – no moving parts means no damage, no noise and better durability - Multiple Colorbond® colours plus a paintable model - BAL-40 compliant - Easy and fast to install on both metal and tiled roofs - Effectively replaces cowl, pipe and flashing (3-in-1) The low-profile roof vent is available in 2 neck sizes – 125/150mm and 150/200mm. Some builders are using a 150-150-200mm y-piece and are venting two fans through the 150/200mm sized model. |

|

Shop online for Roof Vent Kits

10.8.2 Eave Venting

|

Venting out of the eaves is low cost, visually discrete and has a very low likelihood of leaking. For homes that have eaves, this can be a great alternative. An eave vent with a neck for attaching ducting is required. For venting at the eaves, Alpine Ventilation has two options – a snap in version and a screw in eave vent. The snap in version is preferable for faster installation, longer neck for attaching ducting and a higher BAL rating (BAL-29 vs BAL-19) The snap in version comes in two different face designs. The 4 spring loaded clips clasp the eave when the vent is pushed up from the underside. Snap in eave vents are available in 3 neck sizes – 150mm, 200mm and 250mm. Whilst multiple appliances may be exhausted via a larger vent, the 150mm size is the most popular option. |

|

10.8.2 Wall Venting

|

Venting via the wall is usually an option, using either metal or plastic vents with a neck to attach ducting. Wall venting can be a good alternative for houses that do not have eaves. Metal is ideal for durability, superior aesthetics and BAL-40 compliance – and Alpine Ventilation has a full range of aluminium weatherproof louvres. The brick sized BV150 model is extremely popular for its looks and ease of installation. Plastic options include grille vents and gravity vents (which include flaps to prevent backdrafts). Our plastic vents include steel mesh and are BAL-19 compliant. |

|

10.8.3 (Ventilation of Roof Spaces)

Our region in the Hunter Valley sits in climate zone 5, roof ventilation is not mandatory, and the traditional, rotary vents are commonly used – however they are visually prominent, have moving parts that can become damaged or make noise and can leak in low wind conditions.

Some metal roof manufacturers offer venting under the ridge capping. This can be a great, unobtrusive method of venting if available – however can be expensive and must be planned for and installed early in the build process.

Alpine Ventilation has a range of mushroom cowls with pipe and flashing.

Shop online for Low Profile Roof Vents

However, we recommend the use of low-profile roof vents for the following reasons:

- Static – no moving parts means no damage, no noise and better durability

- Easy and fast to install on metal and tiled roofs

- Multiple Colorbond® colours plus a paintable model

- Visually appealing and discrete – can even install under a solar panel

- BAL-40 compliant

For the venting at the eave component, Alpine Ventilation has two 400x200 metal eave vent options.

The new SEV2040W has some advantages – greater open area (21,000 to 19,000), enhanced aesthetics and increased durability (constructed from 0.9mm galvanised steel). Both are BAL-40 compliant.

Alpine Ventilation has developed comprehensive and innovative solutions to further decrease health risks and building damage associated with high moisture levels in new homes that are: attractively designed, visually appealing, cost effective, BAL rated and easy to install. To learn more, read Alpine's Condensation Management Handbook.