At NHS, we understand that as a builder, you need materials that are up to code, reliable, and safe for your projects. That’s why we’re sharing insights from a comprehensive 15-month investigation conducted by Rondo into imported steel wall and ceiling products. This investigation, which involved six rounds of independent laboratory testing on materials from five Australian suppliers importing steel from China, uncovered critical concerns regarding compliance, quality, and durability.

In this first instalment of our two-part series, we’ll focus on two key areas of concern:

- Base Metal Thickness (BMT)

- Zinc coatings.

These findings are vital for making informed decisions about the materials you choose to ensure your projects meet the highest standards.

Base Metal Thickness (BMT): A Vital Specification

What Is BMT?

Base Metal Thickness refers to the uncoated thickness of steel before any treatments are applied. It is a critical factor for determining a steel component’s strength, structural integrity, and suitability for specific applications.

Non-Compliance With Standards

According to Australian Standard AS/NZS 4600, cold-formed steel must retain at least 95% of its designed thickness to be compliant. Rondo products not only meet these standards but also adhere to the rigorous Lloyd's Register Quality Assurance ISO 9001 certification, which in many cases exceeds the requirements of AS/NZS standards, ensuring superior quality and reliability.

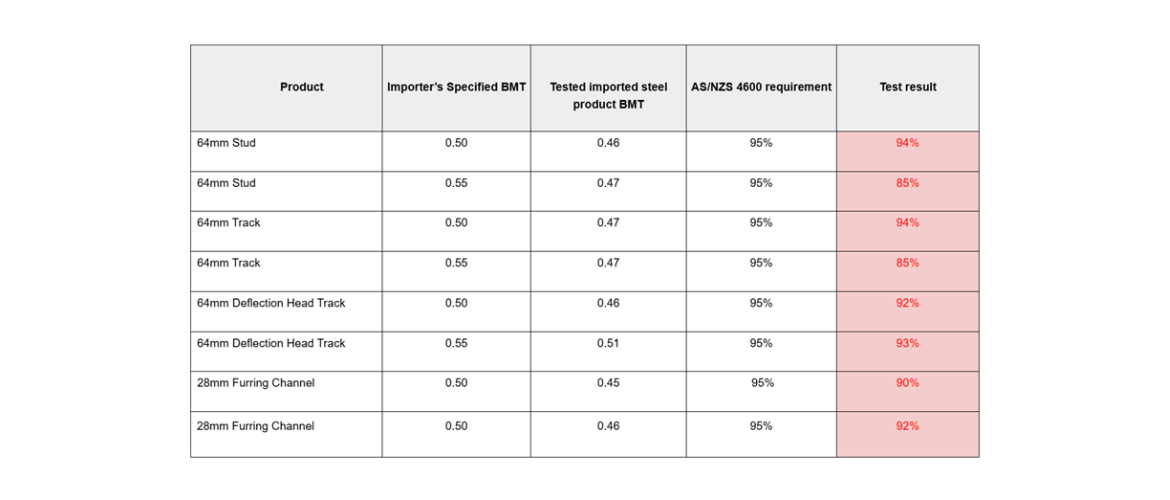

However, Rondo’s investigation revealed many imported components fell short of AS/NZS 4600, with measurements as low as 85-94% of their advertised BMT.

- Steel studs marketed as 0.50 BMT were found to measure between 0.46-0.47 BMT.

- Furring channels labelled 0.50 BMT measured between 0.45-0.46 BMT.

- Some products labelled 0.55 BMT measured just 0.47-0.48 BMT.

Test results of some of the wall and ceiling components Rondo tested:

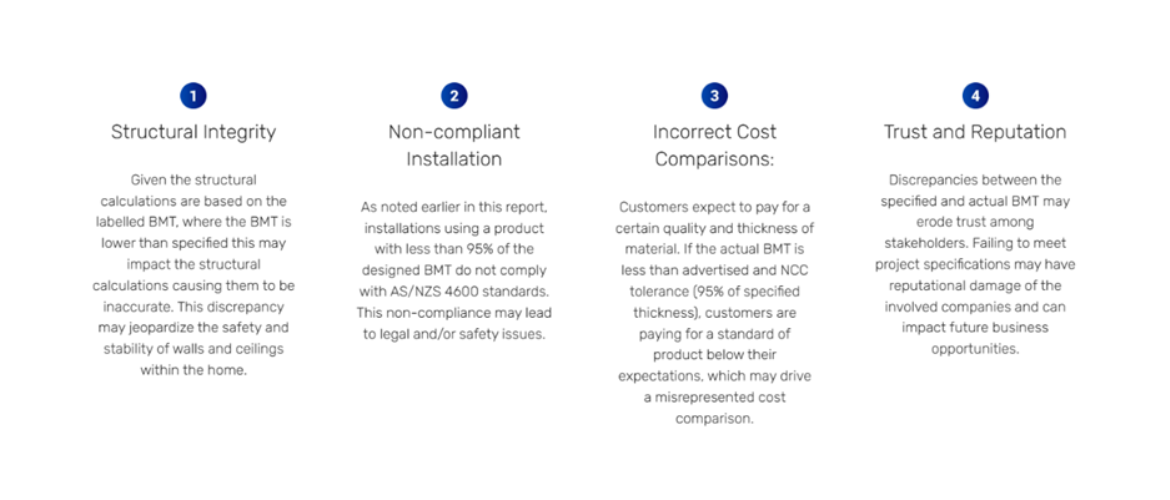

Why It Matters

These discrepancies compromise the load-bearing capacity of the materials. For safety-critical applications, such as fire-rated walls, ceilings, and external walls, using steel that doesn’t meet the required thickness can result in serious structural failures.

Possible implications of reduced Base Metal Thickness (BMT):

Misleading Labels

Rondo’s investigation also found that some suppliers list inflated BMT specifications in their product catalogues. For example, steel studs labelled as 0.50 BMT and tracks as 0.55 BMT were shown in tests to be significantly thinner, misleading contractors who rely on accurate specifications for project designs.

Zinc Coatings: Essential for Corrosion Protection

What Is Zinc Coating?

Zinc acts as a sacrificial layer to protect steel from rust and corrosion. It’s especially crucial in environments prone to moisture or salt exposure, such as coastal areas or external applications.

Non-Compliance With Standards

The Australian Standard AS/NZS 2785:2020 recommends:

- Z180 as the minimum zinc coating for internal ceilings more than 300m from breaking surf.

- Z275 for external ceilings more than 1km from saltwater.

However, Rondo’s testing revealed that many imported products often fell short, with coatings as low as Z100, providing insufficient protection against rust.

Testing Results

- Imported steel studs and tracks labelled 0.50-0.55 BMT had zinc coatings between 85-122 g/m², significantly below the Z275 coating offered by higher-quality alternatives.

- Deflection head tracks, commonly used externally, were found to have coatings of only 171-179 g/m².

Why It Matters

Subpar zinc coatings accelerate steel corrosion, undermining the longevity of structures. Rust can appear years after installation, leading to costly repairs or replacements.

Implications for Builders

Rondo’s investigation underscores the serious consequences of using non-compliant steel products:

Safety Risks: Inadequate strength or corrosion protection can result in material failures, endangering occupants and workers.

Legal and Financial Liabilities: Using materials that don’t meet Australian Standards can lead to non-compliance penalties or project delays.

Hidden Defects: Since steel is often concealed by plasterboard or other materials, issues may not become apparent until failure occurs.

Steps to Protect Your Projects

- Ask for Test Data: Request detailed, independent testing results for BMT and zinc coatings.

- Check Compliance: Ensure products meet AS/NZS 4600 and AS/NZS 2785:2020 standards.

- Verify Specifications: Confirm that what’s advertised aligns with actual product performance.

- Prioritize Quality: Choose suppliers with a proven track record of compliance and durability.

The Bottom Line

Rondo’s investigation highlights the risks of using non-compliant steel products, emphasizing the importance of vigilance when sourcing materials. Builders must proactively assess and verify the quality of steel components to ensure the safety, durability, and compliance of their projects. When it comes to structural materials, scrutiny can prevent costly issues and safeguard your work for years to come.

To view the full report of Rondo's investigation, Click Here.

To visit the whole range of Rondo products at NHS, Visit our online store.